Stainless Steel Mild Steel 550mm

Package Size 21000.00cm * 2100.00cm * 1050.00cm Package Gross Weight 500000.000kg 1. Brief Introduction This unit produc

Description

Basic Info.

| Model NO. | 1450mm |

| Condition | New |

| Power Source | Electric |

| Automatic Grade | Automatic |

| Type | Steel-Making Equipment |

| Certification | ISO, SGS |

| Main Rolling Mill Motor | 1400kw |

| Max Uncoiling Speed | 500 M/Min |

| Output Product Thickness | 0.20~1.5mm |

| Output Product Width | 800~1250 mm |

| Output Product Max Coil Weight | 26t |

| Max Rolling Speed | 1200 M/Min |

| Threading Speed | 30 M/Min |

| Rated Rolling Speed | 500 M/Min |

| Max Rolling Torque | 150 [email protected] |

| Max Rolling Force | 20000 Kn |

| Transport Package | Plywood Box |

| Specification | SGS |

| Trademark | MoRan |

| Origin | Hebei Langfang |

| HS Code | 8455221000 |

| Production Capacity | 100, 000-250, 000 Tons/ Year |

Packaging & Delivery

Package Size 21000.00cm * 2100.00cm * 1050.00cm Package Gross Weight 500000.000kgProduct Description

1. Brief Introduction

This unit produces the thickness of 2.0 ~ 4.5mm pickling hot-rolled coil, by if the road rolling, rolling into 0.20 to 1.5mm high-accuracy Cold rolled steel coilsl scale for the production of cold rolled steel volume 22.5 million tons / year production line of the cold rolling mill, using 6-hi UCM type single stand reversing cold mill, mill work roll is provided with a positive and negative bending and intermediate roll set is bending roll and tic, supporting a uncoiler, frame and are equipped with tension coiler, thickness gauge and laser velocimeter, tensiometer measurement etc., can achieve high tension rolling, ensure the thinner gauge products high and stable production.

2. Technical Specification

| Blank Specification | |

| pickled hot rolled coils Material: | Carbon construction steel, low alloy steel |

| Material performance: | σs≤360N/mm2 σb≤560N/mm2 |

| Thickness: | 1.5~4.0 mm |

| Width: | 800~1250 mm |

| Coil ID: | Φ610 mm |

| Coil OD: | Φ900~Φ2000 mm |

| Max coil weight: | 26t |

| Unit coil weight: | Max23Kg/mm |

| Coil tower: | ≤30mm |

| Strip convexity: | ≤60μm |

| Strip cross section wedge: | ≤40μm |

| Strip surface bulge: | ≤12μm |

| Camber: | ≤5mm/2000mm |

| Width tolerance nominal width: | 0~+10 mm |

| Output product | |

| Thickness: | 0.20~1.5mm |

| Width: | 800~1250 mm |

| Coil ID: | Φ610mm |

| Coil OD: | Φ900~Φ2000 mm |

| Max coil weight: | 26t |

| Main technical data | |

| Max rolling force: 20000 kN | Backup roll size: Φ1150/Φ1250×1450 mm |

| Max rolling torque: 150 kN·m | Pay-off reel drum diameter: (expansion/shrink) Φ620/Φ570 m(nominalΦ610mm) |

| Max rolling speed: 1200 m/min | Tension reel drum diameter: (expansion/shrink) Φ610/Φ585 mm |

| Rated rolling speed: 500 m/min | Rack upright cross section: 760×620=471200 mm2 |

| Threading speed: 30 m/min | Work roll min. openness: 20mm |

| Max uncoiling speed: 500 m/min | Work roll positive/negative bending roll force(single roll unilateral): 400/200 kN |

| Max coiling speed: 1260 m/min | Middle roll positive bending roll force (single roll unilateral): 500kn |

| Uncoiling tension: 7~70 kN | Middle roll sidesway volume: ±325 mm |

| Coiling tension: 8~150 kN | Common hydraulic drive system pressure: 14 MPa |

| Work roll size: Φ355/Φ395×1450 mm | Balance bending roll system pressure: 28 Mpa |

| Middle roll size: Φ420/Φ470×1480 mm | Screw down system pressure: 28 Mpa |

| Line main motor power | |

| Main rolling mill motor | 1400kw 400/1100 rpm total 4 sets |

| Left, right tension reel motor | 1250kw 310/1050 rpm each two sets |

| Pay-off reel motor | 510kw 375/1250 rpm one set |

| Straighter motor | 30kw one set |

| Entry, exit deflector roll motor | 30 kw each one set (AC motor) |

| No. | Incoming thickness(mm) | Outputthickness(mm) | Incomingwidth (mm) | Coil weight (t) | Annual output | ratio(%) |

| 1 | 2 | 0.2 | 1100 | 20 | 5000 | 2 |

| 2 | 2.3 | 0.25 | 1100 | 20 | 7500 | 3 |

| 3 | 2.75 | 0.35 | 1200 | 20 | 50000 | 20 |

| 4 | 3.0 | 0.45 | 1200 | 22 | 75000 | 30 |

| 5 | 3.0 | 0.5 | 1200 | 22 | 87500 | 35 |

| 6 | 3.5 | 0.7 | 1300 | 25 | 12500 | 5 |

| 7 | 3.5 | 1.0 | 1300 | 25 | 7000 | 3 |

| 8 | 4.0 | 1.5 | 1300 | 25 | 5000 | 2 |

| Total | 200000 | 100 |

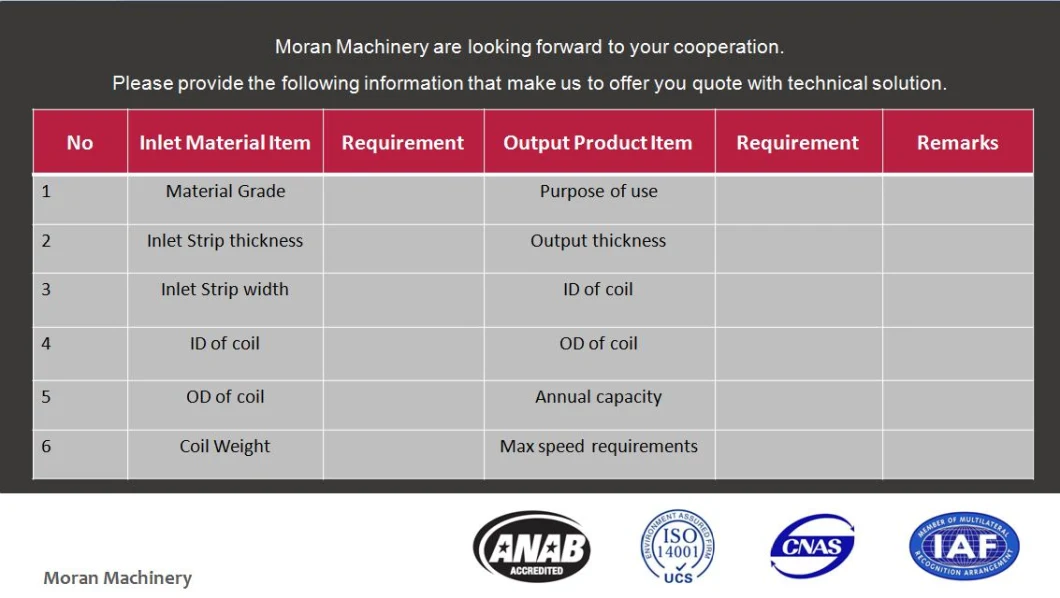

You are warmly welcomed to visit our workshop.Moran Machinery are looking forward to your cooperation.Liu Huan (Tony Liu)Our website: Moranchina.en.made-in-china.com

Prev: Skew Rolling Mill for Steel Ball Cold Roll Forming Machine

Next: Hot Rolling Mill Production Line with Straightener and Cold Saw, Stacker, Bundling Machine

Our Contact

Send now